For the past decade, traditional air-cooling with CRAC, CRAH, and fan walls have been the industry workhorse. Pump a lot of air across the room, perhaps with containment aisles, fix the hotspots, and for the most part, it keeps systems in range. But today, escalating rack and heat densities are surpassing what traditional air cooling was ever designed to handle.

Consider the NVIDIA DGX H200, with 8 GPUs drawing 10.2kW of power. Six of these can fit in a 48U rack, creating a 61kW rack. On the roadmap are GPUs that will continue driving heat densities upward—well beyond what traditional air-cooling can manage. As fan speeds rise to compensate, efficiency falls and energy costs increase. NVIDIA CEO Jensen Huang has already indicated that racks drawing around 200kW are already emerging, and its public roadmap points to designs approaching 600kW within just a few years. This shift underscores the limits of air cooling and the growing necessity for scalable liquid cooling solutions.

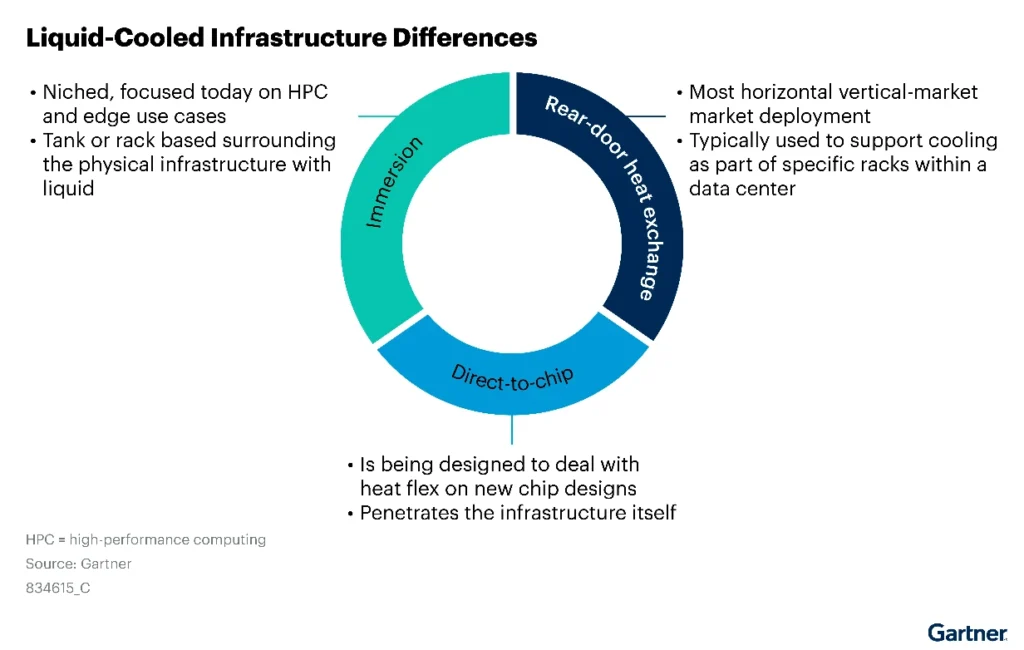

Liquid Cooling Differences

When things get hot, liquid cooling is usually the answer. Thanks to its high heat capacity, liquid cooling efficiently manages workloads that air-based systems can no longer handle. Three distinct approaches exist:

- Rear door heat exchangers (RDHx)

- Direct-to-chip (DTC)

- Immersion Cooling

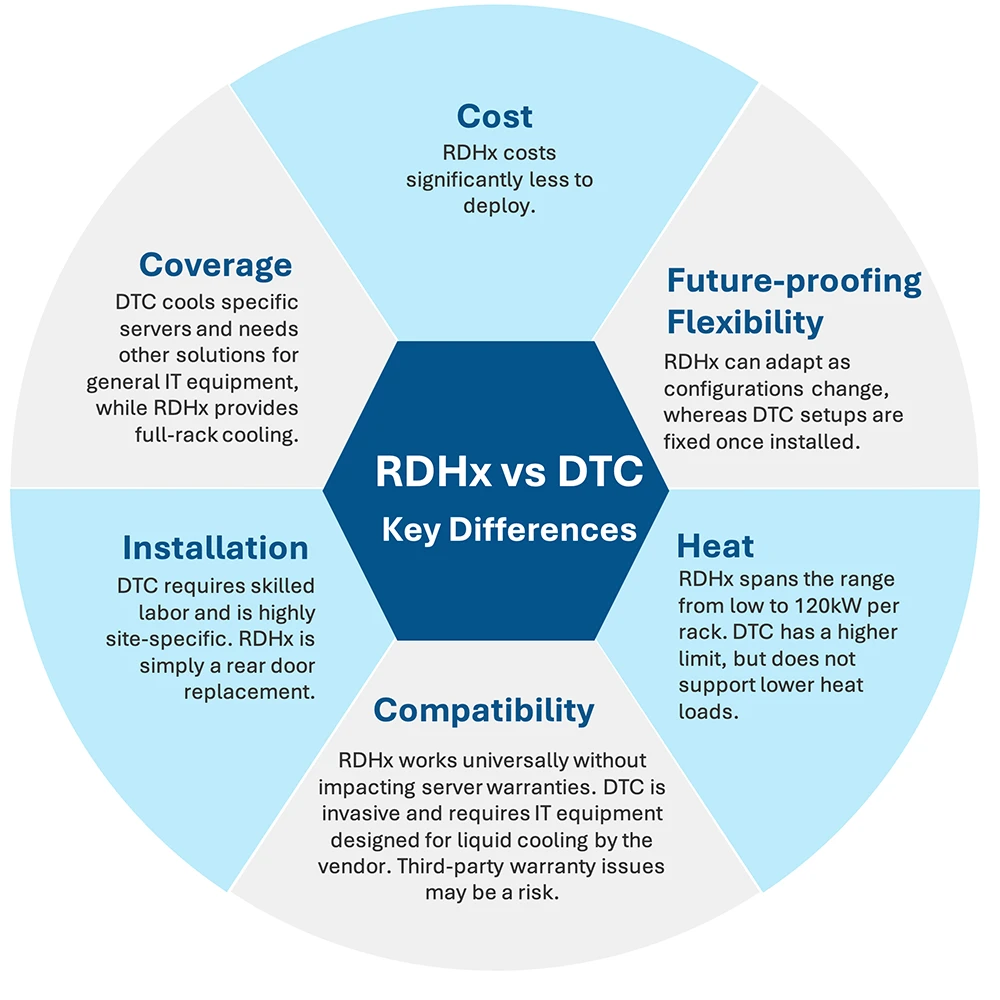

DTC and immersion cooling systems are designed to support ultra-high heat loads, but they require specialized infrastructure and upfront investment. On the other hand, RDHx systems are designed for a wide range of heat loads – from traditional enterprise racks to AI/HPC racks up to 120kW – making them the most versatile choice.

Why RDHx is the Practical, Low-Risk Choice

Traditional air-cooling cools the entire room. RDHx cools at the rack level, providing only the cooling that each rack actually requires. Rear doors often include reserve capacity that can be used immediately, without reconfiguring the rack, interrupting workloads, or bringing in skilled labor. If additional cooling is needed, the door can simply be upgraded to a higher-capacity model.

Depending on the design, RDHx systems may return either conditioned or warm air to the room. Two-phase RDHx systems, like OptiCool’s, extract heat and expel room-neutral air, enabling them to work seamlessly with existing air-cooling systems, or operate independently. This flexibility makes it possible to add AI and HPC racks with power densities up to 120kW incrementally as demand grows, without major upfront infrastructure changes. And with AI hardware evolving so quickly, long-term adaptability matters. Unlike DTC and immersion systems, which are vendor-specific and locked to AI workloads, RDHx doors can be redeployed to standard racks when equipment ages out, continuing to reduce load on legacy air systems.

Liquid cooling:Single-phase vs. 2-Phase

Most liquid cooling solutions rely on water and operate in single-phase mode. OptiCool’s RDHx is different: it uses a refrigerant in a 2-phase system that leverages phase change for maximum efficiency. When refrigerant absorbs heat, it vaporizes instead of rising in temperature, unlocking enormous heat capacity at the boiling point.

This design:

- Extracts heat from the room rather than simply introducing cold air, creating a more efficient thermal cycle.

- Delivers higher capacity, unlike single-phase systems that rely on more flow or larger equipment to handle higher densities, two-phase cooling achieves higher heat removal in a smaller footprint.

- Uses less energy, by harnessing thermodynamics, two-phase systems require significantly less power to extract heat. OptiCool’s 60kW door, for example, operates at just 800 watts for the pump and 790 watts for the door.

OptiCool is the only vendor offering 2-phase refrigerant RDHx technology, combining the versatility of rear door cooling with the efficiency of phase change systems.

Learn more about our new 120kW RDHx — the highest-capacity rear door heat exchanger on the market.