MITRE was the first company in New England and one of the first enterprises in the U.S. to implement an innovative refrigerant-based cooling solution to support its computing facility in Bedford, Massachusetts. After four years, MITRE’s High-Performance Compute Center is a dramatic example of how progressive thinking and solid system analysis can deliver effective solutions to a complex problem.

Meeting The Increased Demand For Computing Power

In 2013, the MITRE data center, which used traditional raised-floor air flow cooling, had reached its limits in both overall capacity of 290 kilowatt (kW) and thermal density of 2.5 kW per computer server cabinet. To solve this fundamental problem, the MITRE team painstakingly examined how to most efficiently support the increasing demand for higher density compute and lab services at MITRE.

The MITRE Team evaluated a variety of approaches, including 1) building a new on-premise commercial data center, 2) moving to an off-premise commercial data center, 3) moving to cloud-based hosting services, or 4) retrofitting the existing data center. An exhaustive analysis was undertaken to assess each option in terms of performance, capacity, efficiency, initial and long-term costs. Based on the results of the analysis, MITRE selected the R134a refrigerant-based active rear-door solution provided by OptiCool Technologies.

A key factor in selecting the OptiCool solution is its efficiency in providing “close-coupled” cooling by transferring heat from inside the cabinets directly to the refrigerant. This eliminates the “hot-aisle/coldaisle” problem entirely, meaning the data center only requires enough air conditioning to make the space comfortable for people. Another key factor was the flexibility of the modular OptiCool heat exchanger’s ability to provide 10, 20, or 30 kW of cooling per cabinet.

The Cooling Solution That Delivers True ROI

By the summer of 2015, MITRE completed the installation and commissioning of the new OptiCoolbased High Performance Compute Center. After four years with the new design, the OptiCool solution has definitely paid off. MITRE has achieved a more than a ten-fold increase in power and cooling density, and at the same time has reduced internal data center cooling costs by 90%, and overall cooling costs by 20%. In addition, MITRE was able to consolidate data center cabinets, which dramatically reduced costs and increased valuable floor space. At MITRE, a smaller footprint plus greater efficiencies adds up to increased ROI.

With this innovative refrigerant cooling system and more efficient power systems installed, the MITRE compute center can now accommodate the increasing demand for high-performance computing projects and Big Data Analytics for sponsors like the U.S. Department of Defense and the Centers for Medicare & Medicaid Services.

Why MITRE’s Cooling Solution Works So Efficiently

Fundamentally, cooling the computer equipment in a data center is about moving heat energy most efficiently. Some data centers use air and some use water, but the OptiCool system uses R134a, a non-toxic, synthetic refrigerant. R134a has superb thermodynamic properties, which make it an ideal medium for moving heat. For a given volume, water can absorb 3,400 times more heat than air. In comparison, R134a can absorb nine times more heat than water making it the lifeblood of MITRE’s cooling solution.

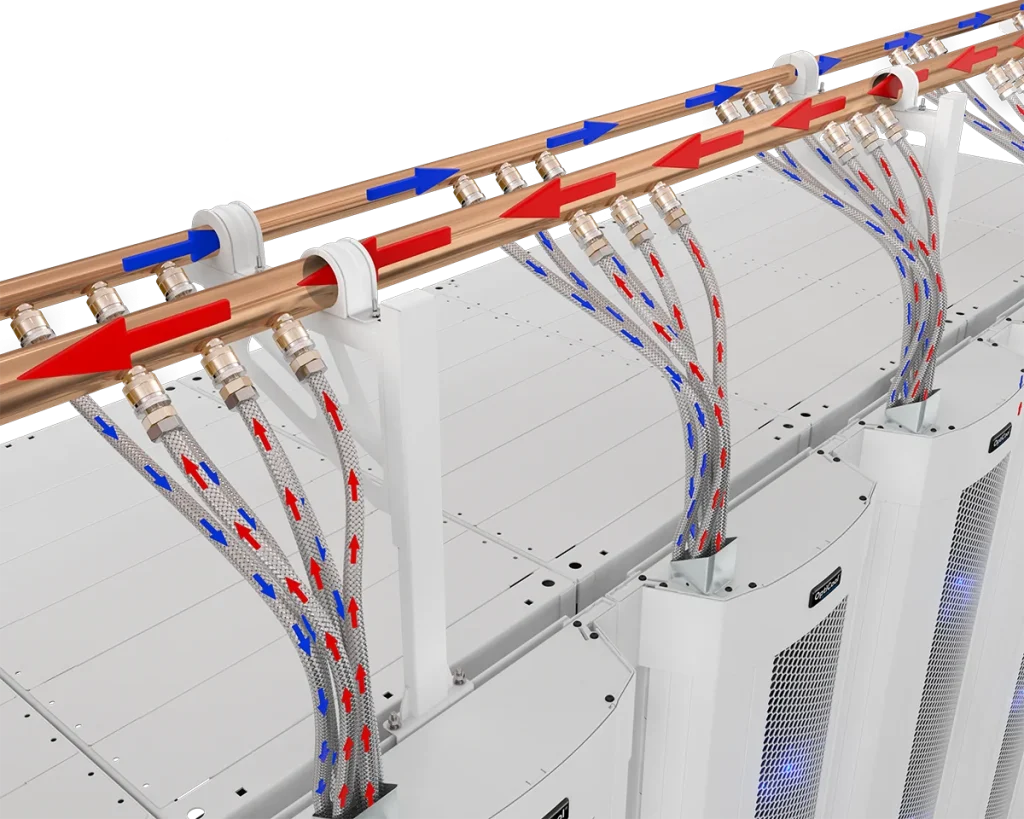

If R134a refrigerant is the lifeblood, then the heart of MITRE’s cooling solution is OptiCool’s refrigerant distribution unit (RDU). The RDU does not have a compressor, rather a small electric motor that is magnetically coupled to an impeller. The impeller circulates the liquid R134a through the refrigerant distribution network (RDN), a series of small diameter copper pipes that extend over the data center cabinets.

From the RDN, the liquid R134a flows through flexible stainless-steel hoses that connect to active heat extractors (AHX) which are mounted in the rear doors of the cabinets. The AHX units are essentially small radiators with fans, each of which can remove up to 10 kW of heat. Up to three AHX units can be installed in a single cabinet.

The AHX fans pull the hot air from the servers through the AHX units. The heat is absorbed into the R134a liquid, which “flashes” into gas via a phase change effect. The heated gas flows through an RDN return pipe to the heat exchanger in the RDU. When the heated gas hits the heat exchanger in the RDU, cold water from the chiller plant absorbs the heat, which is pumped out to MITRE’s central cooling towers. The refrigerant condenses into a liquid state and is pumped back to the cabinets to repeat the process. The RDU is very efficient, requiring only 1.5 horsepower per 250 kW of cooling, which is about the same power needed to run a residential sump pump.